■工作機械の横に設置し使用する標準タイプ

独自機構で生成された水溶性ミストをタレット給油経路や小型/中型のマシニングセンタのスピンドルスルー/サイドスルーで加工点に供給します。

3 parameters for fine tuning.

Can be finely tuned to match the processing contents and environment.

Adjustable up to a maximum discharge volume of 40 cc/min.

■工作機械の横に設置し使用する標準タイプ

独自機構で生成された水溶性ミストをタレット給油経路や小型/中型のマシニングセンタのスピンドルスルー/サイドスルーで加工点に供給します。

3 parameters for fine tuning.

Can be finely tuned to match the processing contents and environment.

Adjustable up to a maximum discharge volume of 40 cc/min.

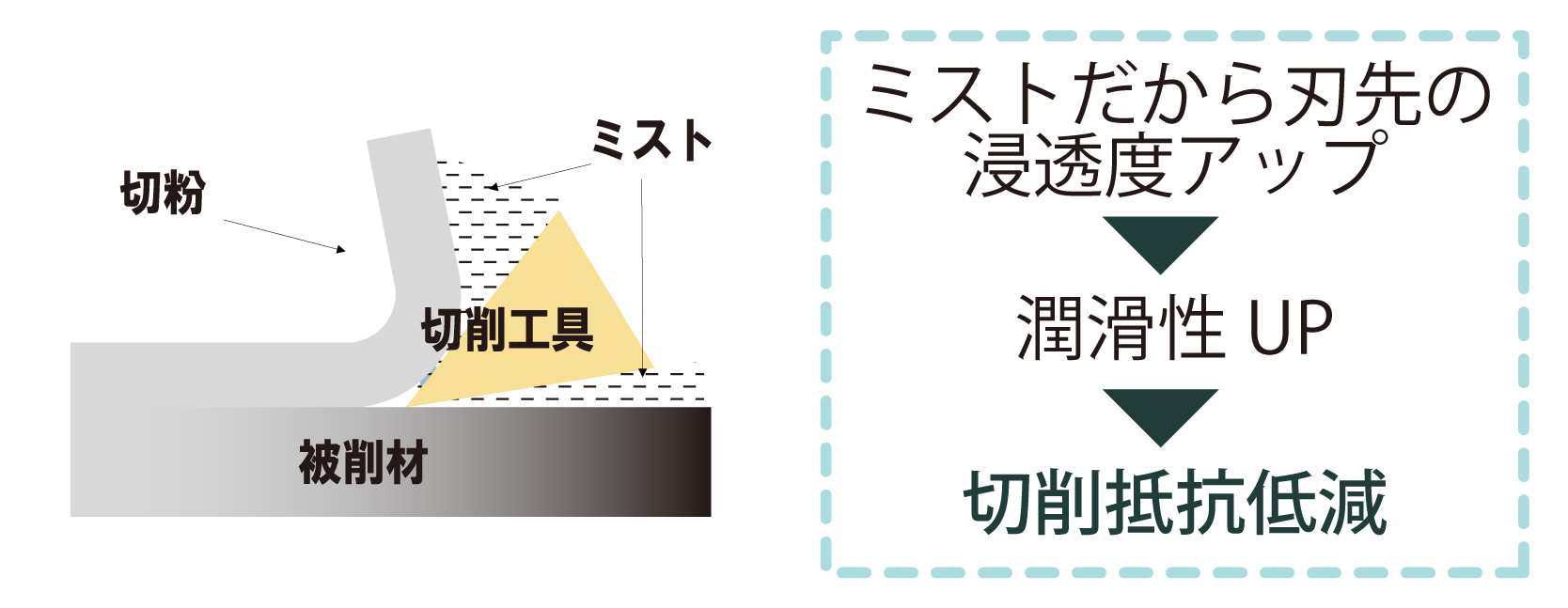

■Processing is possible with a small amount of oil

■Oil cost is also reduced

■No need for industrial waste treatment and chip decoolant treatment

・Amount of spray :max40cc/min

・Special misting liquid usage amount :About 2cc/min.

Workpiece surface immediately after machining

No coolant residue = no need for coolant treatment

| Usage Volume | Amount | |

| Cutting Fluid | 14.0L | 11,660 yen |

| Cutting Fluid Refill | 20.0L | 11,660 yen |

| Coolant motor power | 1kW | 4,420 yen |

| Water | 340.0L | 70 yen |

| Cutting Fluid Replacement | 830 yen | |

| Industrial waste disposal cost | 600 yen | |

| Chip decoolanting cost | 830 yen | |

| Total | 35,070 yen |

| Usage volume | Amount | |

| COOL300 (undiluted solution) | 9.6L | 9,867 yen |

| Equipment power | 110W | 485 yen |

| Air power | 750W | 3,310 yen |

| Water | 192.0L | 39 yen |

| Total | 13,701 yen |

▶Running cost cut by approx. 60%

◆High speed processing and high feed rate

◆Extension of tool life, etc.

◆Improved machining efficiency

| Work | Construction Machinery Parts | |

|---|---|---|

| Material | FCD450 | |

| Industry | Construction Machinery | |

| Processing details |

Drilling | |

| Processing details |

Five-face drilling machine HF-4M made by Shinbon Koki | HF-4M |

▶Machining efficiency increased by approx. 3.5 times, tool life doubled

Mist equipment for large machine tools that can be mounted on large machine tools. Consists of a small machine-mounted unit and a floor-mounted replenishment tank.

Standard machine to be installed beside the machine tool

Supplies mist to machining points in the turret lubrication path of single turret lathes and spindle-through/side-through of small/medium machining centers.

For machines such as multi-turret lathes that require mist to be supplied from multiple nozzles at different times, or hobbing machines that require a larger volume of mist.

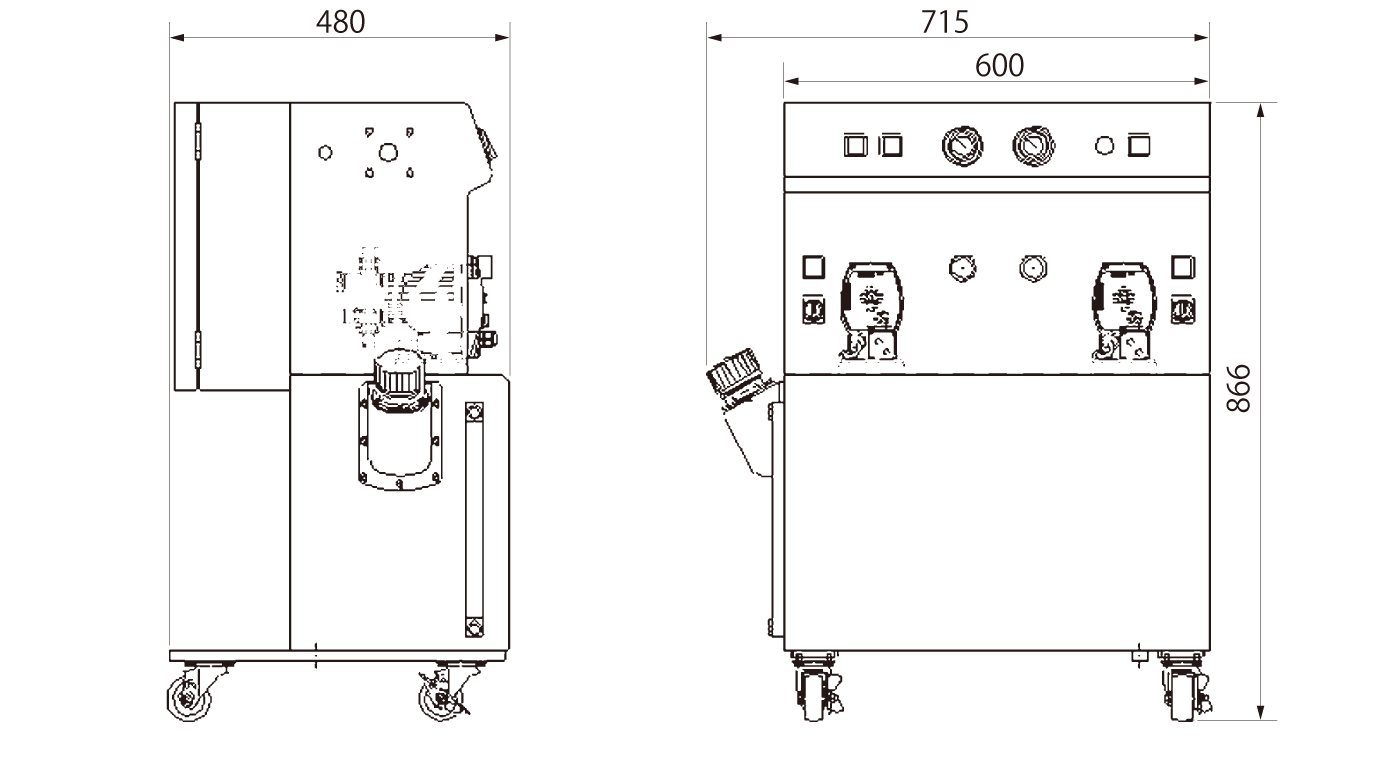

| Machine Dimensions | W715×D480×H866 | |

|---|---|---|

| Pump type | Electromagnetic metering pump: 1 unit | |

| Maximum discharge volume: 40cc/min | ||

| Minimum discharge volume: 0cc/min | ||

| Maximum discharge pressure: 1.0MPa | ||

| Required air pressure | Normal: 0.3 to 0.7MPa | |

| Air consumption | Maximum 250L/min | |

| Coolant spray volume | 0〜40cc/min | |

| Power source | Single phase 200V 50/60Hz | |

| Tank capacity | 68L | |

| Weight (dry weight) | 58kg | |

M-1 and M-2 share the same external dimensions. ※The figure is M-2