High pH alkaline ionized water generator AG-80/AG-240

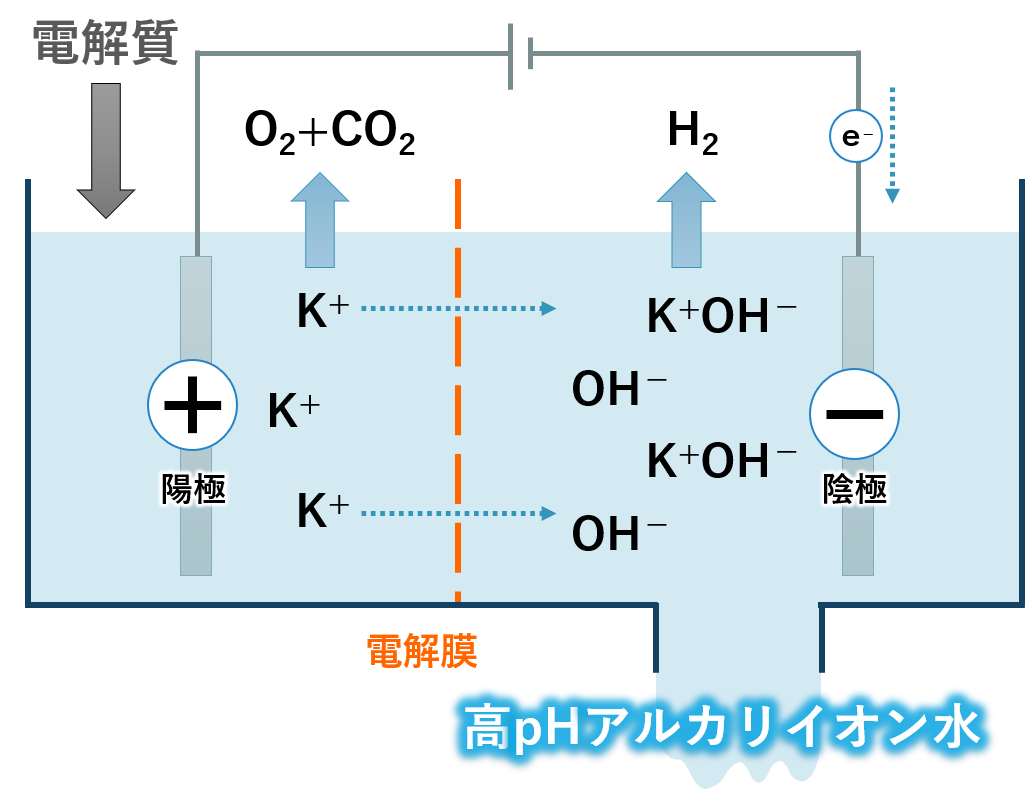

1 Eco-friendly design that produces no effluent

Does not generate any acidic water or chlorine gas as waste liquid. Enhanced environmental performance specifications that do not use any chemicals

2 Generates high pH alkaline ionized water with a pH of 13.2, which is easy to adjust and manage

"Generates high pH alkaline ionized water (electrolyzed water) with pH 13.2 using our unique electrolysis technology.

Generates 80L~240L/day of alkaline ionized water efficiently and at low cost.

High pH allows simple pH adjustment of cleaning and cutting fluids with a small amount."

3 Easy 3-step operation

- ① Drop in the special additive.

- ② Easy operation with touch panel.

- ③ All you have to do is wait!

Features of high pH alkaline ionized water

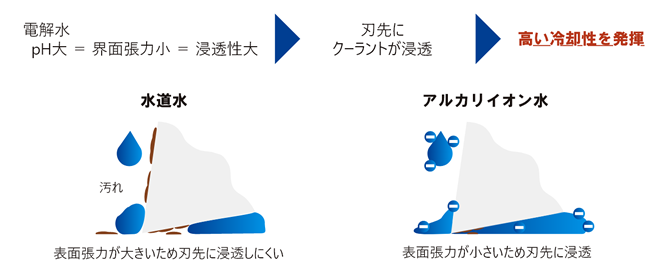

① Penetrating and cooling properties

Cool Tech's alkaline ionized water (electrolyzed water) reaches a pH of 13.2 or higher. Water with a high pH has finer water molecules and smaller interfacial tension. As a result, it shows high permeability.

Water with higher permeability can be expected to improve productivity in grinding and cutting operations, as it can penetrate the cutting edge and provide a high cooling effect.

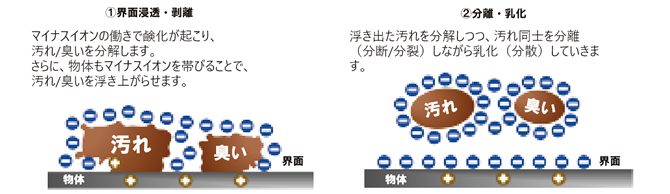

② Cleaning power

Water with high permeability will be able to penetrate into the crevices of dirt. In addition, the negative ions of alkaline ionized water (electrolyzed water) envelop dirt and lift the dirt itself, resulting in a cleaning effect.

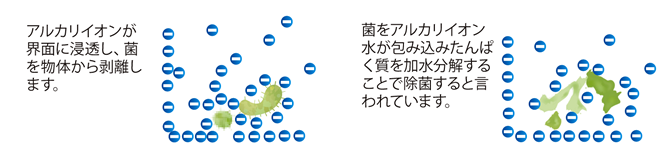

③ Sterilizing and deodorizing effects

Alkaline ionized water exhibits high sterilizing performance. By mixing it with cutting fluid, it can prevent cutting fluid from decomposing and eliminate putrid odors, thereby improving the working environment.

④ Anti-rust effect

Alkaline ionized water creates a passive film on the surface layer of ferrous metals, making them less likely to rust in alkaline ionized water.

Productivity Improvement/Cost Reduction

Improvement of lathe machining efficiency

The machining time needed to be shortened in order to increase efficiency.

・Cutting speed increased by 30%.

・Both dimensional accuracy and surface roughness cleared the target values.

Cutting speed S230m/min ▶︎ Cutting speed S299m/min

| Workpiece name | Gear hub |

|---|---|

| Material | SCM425 |

| Industry | Construction machinery |

| Machining Contents | Contents : Lathe machining |

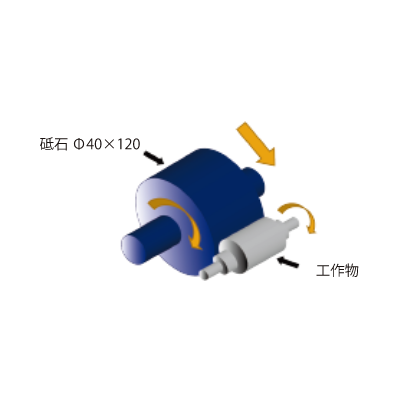

Grinding difficult-to-machine materials and extending tool life

Tool life was a problem in grinding difficult-to-machine materials.

Number of passes to tool life (dressing)

5 times ▶︎ 16 times Grinding wheel life 3 times improved

Grinding distortion amount: 1/3 / Depth of cut: 1.7 times ▶︎ Accuracy and efficiency increased

Reduction of thermal softening due to grinding burning

| Material | thermal softening due to grinding burning is also reduced. |

|---|---|

| Machining Contents | Grinding |

Reduction of oil usage

Switching from insoluble to water-soluble coolant

① Coolant has high permeability and cooling properties.

② Suppresses changes in condition such as deformation of the cutting tool and base material due to heat.

③ Maintain high precision machining even after switching to water-soluble coolant.

Results of introduction

・Significant reduction in the amount of cutting fluid used

・Significant reduction of cutting fluid wast

・ Avoided regulations such as the Fire Service Act.

| Work | SCM420H |

|---|---|

| Industry | Construction Machinery |

| Machining Details | Hobbing |

For water-soluble cutting fluid coolant

① High permeability and coolability of coolant.

② Reduce the oil standard concentration of water-soluble coolant。

③ Alkaline ionized water (electrolyzed water) reduces the interfacial tension of water-soluble coolant.

④ Water drainage is improved and oil carried out by chips is reduced.

⑤ Reduction in the amount of oil used for replenishment.

Results of introduction

Standard concentration 4 to 5% ▶︎ Standard concentration 2 to 3%

Replenishment oil concentration 4 to 5% ▶︎ Replenishment oil concentration 1 to 1.5%

| Work | Shafts |

|---|---|

| Material | SCM |

| Machining Details | Turning |

Improved working environment

Prevention of cutting fluid spoilage/improvement of spoilage odor

| Work | Hydraulic Motor Case |

|---|---|

| Material | FCD450 |

| Industry | Construction Machinery |

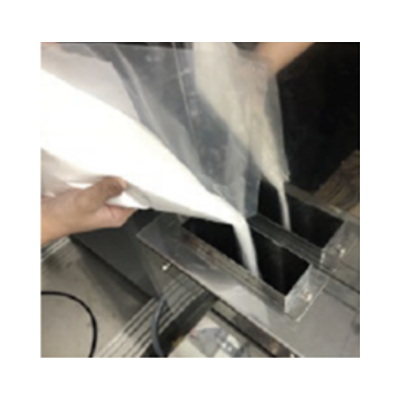

Example of adoption (as a detergent in cleaning lines)

Application examples in parts/equipment/line cleaning

|

|

|

|

|

| Object to be cleaned | Product box | Gears for construction machinery manufacturer | assembly line | General parts cleaning |

| Tank capacity (L) | 400 | 260 | 260 | 200 |

| Daily replenishment volume (L) | 20 | 5 | 10 | 10 |

| Previous cleaning solution replacement standard | After decomposition | Periodic replacement 1 month | Periodic replacement 1 month | Periodic replacement 1 month |

![]()

| Standard for replacement of cleaning solution after introduction of alkaline ionized water | 6 months | 6 months | 6 months | 6 months |

|---|---|---|---|---|

| Periodic Replacement 1 month Alkaline ionized water replenishment to maintain cleaning power |

Extended replacement timing due to no decomposition

|

|||

・Applicable to various cleaning machines ・Cleaning solution replacement cycle is 1/6 or less

Optional products

Cutting fluid

Product name: COOLTEHC CUT CO-300

Application: Grinding/Cutting Fluid

Packing: 18L/can

Dilution concentration: 3-8%

・Combination with alkaline ionized water provides not only penetrating and cooling properties, but also high lubricity.

・Although soluble, it provides lubricity equivalent to that of emulsions.

・It is particularly effective on difficult-to-machine materials, including ferrous and SUS materials.

Product name: COOLTEHC ANTI-RUST for cleaning WA-1

Application: Antirust agent for cleaning

Packing: 4L/bottle

Dilution Concentration: 0.3-0.5%

・Anti-rust is demonstrated at low concentrations for economical use.

・WA-1 can be used at a concentration of 0.3-0.4% for non-ferrous metals and 0.4-0.5% for ferrous metals, while general Antirust agent require a concentration of 3-5%.

・It can be used on steel and cast iron in addition to aluminum, copper, and brass.

Defoamer

Product name: COOLTECH DEFOAMER DF-700

Applications: defoaming of cutting fluids, cleaners, paint booths, etc.

Packing: 2L/bottle

Dilution concentration: 0.006%

・COOLTECH DEFOAMER DF-700 is a newly developed defoaming agent that suppresses foaming of coolant, washing water from washing machines, and water from the tanks of water-rinsing paint booths.

・It is also effective in defoaming high-pressure coolant.

・It is very economical to use because it is effective at a dilution concentration of only 0.006%.

Centralized Coolant Management System for Alkaline Ionized Water

This system automatically supplies cutting fluid to the tanks of each machine tool. By centralizing management, rather than managing it on a per-site basis, this system contributes to the stabilization of cutting fluid quality control.

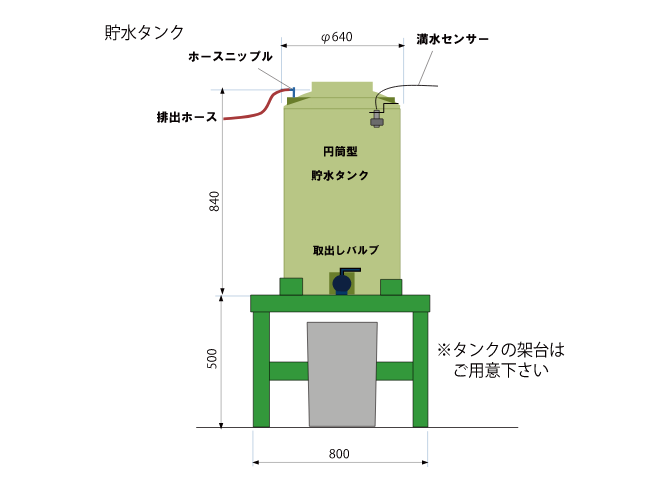

Alkaline ionized water tank and stand

Standard: 200 L. If you require other sizes, please contact us.

Product type

AG series

Standard machine capable of generating high pH alkaline ionized water (electrolyzed water) with pH 13.2.

Eco-friendly design with no waste liquid and food additive-derived additives.

- AG-80

Generates 80L/day of high pH alkaline ionized water (electrolyzed water) . It is used for cleaning, preventing cutting oil from spoiling, and improving grinding productivity. It has a proven track record of operation at factory sites and can stably generate water.

- AG-240

Generates 240L/day of high pH alkaline ionized water (electrolyzed water). It is used for cleaning, preventing cutting oil from spoiling, and improving grinding productivity. It has a proven track record of operation at factory sites and can stably generate water.

Related Products

Product Specifications

Features

| Item | main specification | |||

|---|---|---|---|---|

| Type | AG-80 | AG-240 | ||

| Power source | Single phase 100V 50 / 60Hz |

Single phase 100V 50 / 60Hz |

||

| Power Consumption | 400W | 850W | ||

| pH | 13.2 | 13.2 | ||

| Generation Capacity | Max. 80L/day | Max. 240L/day | ||

| Main unit dimensions (excluding filter unit) |

W500×D500×H1450 ㎜ | W500×D500×H1450 ㎜ | ||

| Weight | Approx. 70 kg | Approx. 70 kg | ||

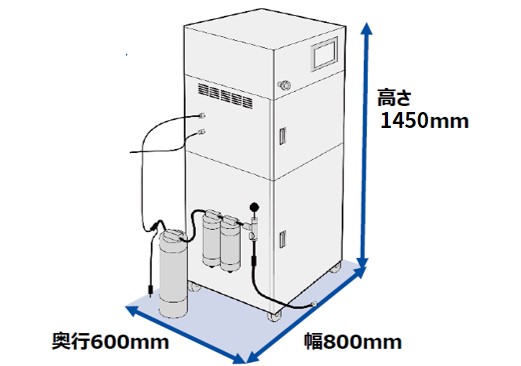

Required range of main unit installation

AG-80/240

Tanks and stands